“When I animated a chemical flow in EdrawMax and exported it to PowerPoint. Suddenly, our R&D team could see phase changes, not just read about them. It turned static diagrams into storytelling tools.”

Luis Fernando Camargo

Automation Terminals Product Management Team Leader, Mettler Toledo

Mettler Toledo is a global leader in precision instruments and analytical solutions, renowned for its commitment to accuracy and innovation in industries that demand exact measurements and reliable performance. With decades of expertise in delivering high-quality scales, laboratory instruments, and process control systems, the company has established itself as a trusted name among professionals who value precision and dependability. For Mettler Toledo, visual communication of complex processes is critical in driving product development and ensuring effective collaboration across departments.

Luis Fernando Camargo, the Automation Terminals Product Management Team Leader, plays an essential role in bridging the gap between research and development, marketing, and project implementation. His daily responsibilities involve creating intricate diagrams and detailed process layouts that serve as blueprints for innovation. Reflecting on his experience, Luis mentioned, "I get in love with a product, so I bought it," underscoring his passion for tools that enhance the clarity and precision of technical designs. His enthusiasm soon spread across the company as his meticulously crafted visuals became a benchmark for excellence, helping teams align their efforts and communicate ideas more effectively.

This drive for excellence in internal communication led Mettler Toledo to search for a solution that could keep pace with their dynamic, complex workflows—a tool that not only supported precise technical drawings but also fostered a creative and collaborative environment.

Measurement Solutions. Image Courtesy - mt.com

Challenges

Before transitioning to their new diagramming tool, Mettler Toledo faced several hurdles that limited efficiency and stifled innovation. Their previous software offered a limited range of industry-specific libraries, forcing engineers to manually redesign essential components such as actuators and valves. Luis recalled that this gap in functionality meant extra work and a risk of inconsistencies in technical documentation, hampering the precision required for their critical projects.

Additionally, the existing solution produced visual outputs that were subpar, resulting in diagrams that failed to capture the complexity of industrial processes. This lack of clarity not only impeded effective cross-department communication but also made it difficult to convey intricate process flows during product development meetings and training sessions. The static nature of the diagrams left stakeholders with a limited understanding of the dynamic interactions within the systems, ultimately reducing the impact of their presentations.

Moreover, the inability to integrate dynamic animations and 3D drawing capabilities meant that the simulation of real industrial processes remained rudimentary. Luis emphasized that “the lack of dynamic animation and 3D drawing capabilities hindered effective simulation and demonstration of real industrial processes.” Without these advanced features, teams struggled to illustrate operational nuances, which further complicated internal discussions and slowed down the decision-making process. These challenges collectively underscored the need for a robust, flexible solution that could support the complex demands of the industrial environment.

Solutions

Their search led them to Wondershare EdrawMax, a solution that promised a comprehensive library of industry-specific icons and an intuitive interface capable of meeting the high standards of technical communication demanded by the company.

Luis was quick to note the difference when he switched from his previous tool to EdrawMax. He explained, “I used to use Smart Draw, but I stopped using it because I found EdrawMax,” highlighting the immediate impact of a tool that truly understood the intricacies of industrial diagramming. With a rich PID (Process and Instrumentation Diagram) library provided pre-built symbols for actuators, valves, and other critical components, EdrawMax minimized the need for manual adjustments and ensured that every diagram was both accurate and aesthetically pleasing.

The new solution also brought with it advanced features such as flexible templates, high-definition outputs, and dynamic flow animations. These capabilities enabled the design team to generate visuals that could be seamlessly integrated into various formats, including SVG, JPG, and PowerPoint. By providing an intuitive platform that supported both static and animated diagrams, EdrawMax not only enhanced the quality of the technical drawings but also promoted a more interactive and engaging way of sharing ideas. This innovation allowed Mettler Toledo to foster a unified visual language across departments, significantly boosting internal collaboration and speeding up the product development cycle.

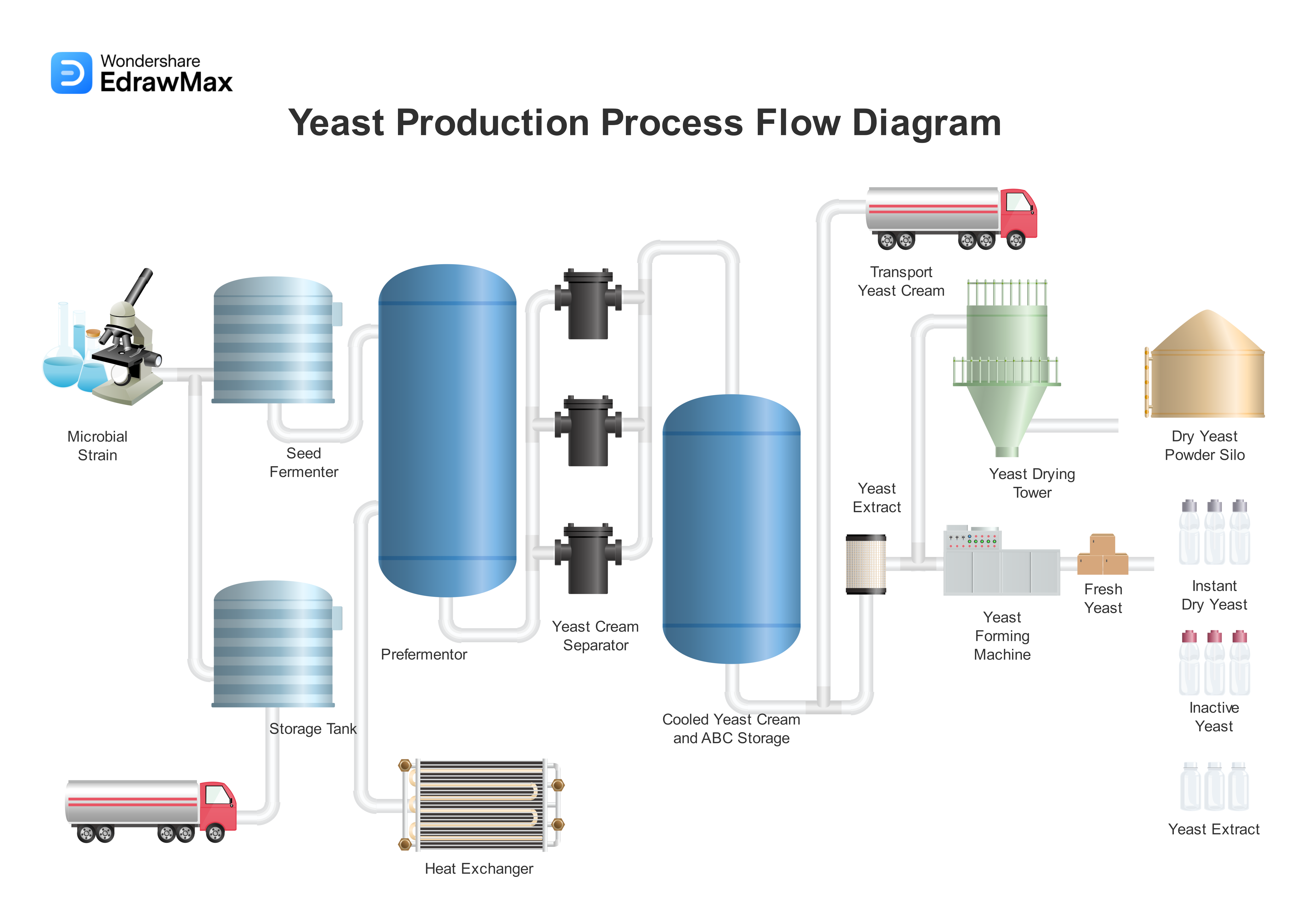

Example of EdrawMax P&ID Diagram

Results

Since adopting EdrawMax, Mettler Toledo has witnessed a marked transformation in its diagramming process and overall internal communication. With the new tool, the time spent on creating detailed industrial diagrams dropped by an estimated 25%, while more than 80% of team members reported improved clarity in technical presentations. Luis’s enthusiasm was contagious—he once remarked how every time his colleagues saw his drawings, they were amazed, leading to a rapid company-wide adoption.

The extensive and tailored icon libraries have reduced the need for manual redesign, allowing engineers to focus more on innovation and less on repetitive tasks. In terms of visual communication, with features like enhanced flow animations and the potential for 3D drawing integration, Mettler Toledo could now better demonstrate real industrial operations. High-definition images and dynamic animations have also made it possible to simulate real industrial processes more accurately, helping to bridge the gap between theoretical design and practical application.

The seamless integration with presentation tools such as PowerPoint further bolstered the tool’s effectiveness, ensuring that every aspect of the company’s communication was aligned with its high standards of excellence. In a world where precision and clarity are paramount, the results speak for themselves—Mettler Toledo is now more agile, collaborative, and forward-thinking than ever before.

Conclusion

For Mettler Toledo, EdrawMax isn’t just a diagramming tool—it’s a catalyst for redefining how industrial challenges are visualized and solved. As Luis puts it, “We’re no longer just documenting processes; we’re animating the future.” With plans to integrate 3D modeling and expand system engineering libraries, the collaboration continues to evolve, much like the company’s commitment to precision in every measurement.

In an industry where clarity drives progress, Mettler Toledo’s story underscores a universal truth: the right tools don’t just solve problems—they illuminate possibilities.